DUCTFABRICATION

METHODOLOGY

Coil stock preferred

material should be of

the minimum gauge

necessary to resist

by internal pressure

turbulent air flow. For

any given pressure class,

gauges are permissible

depending on the

spacing between

transverse joints/

reinforcements. These

shall conform to tables

1-3 to 1-9 of ‘SMACNA’

must be of Lock Forming

Quality (LFQ) conforming

to the standards of

AST A653.

of 180 gms./sq.m.

Yield strength for steel

sheet and reinforcement

should be 30,000 PSI

(207MPa).

failure.

Where a transverse joint acts as a reinforcing member

for ducts up to 48” (1220mm) width (W), and W/2 for

greater widths.

For the spacing of transverse joints and type of

reinforcement refer ‘SMACNA’ tables for rectangular

to 10” (2500 Pa) W.G.

commercial tolerances on out-of-flatness, natural sag from

dead weight and with the flexure reversals that may result

when duct pressure is inadequate to stretch the sheet taut.

Beading is preferred to cross-breaking applicable to 20g

(1.00 mm or less and 3” W.G. (750 Pa) pressure or less.

Ducts for 4” W.G. (1000 Pa) or more do not require beads or

cross-breaks.

of leakage in a system is significantly related to system size.

scaling the duct work.

Transverse Joints should be sealed with gaskets, and for

Longitudinal joints shall

be preferably restricted

to two diagonally

opposite edges.

These should be

machine-formed of any

of the following types:

lock type.

Joints and seams should

be able to withstand

failure.

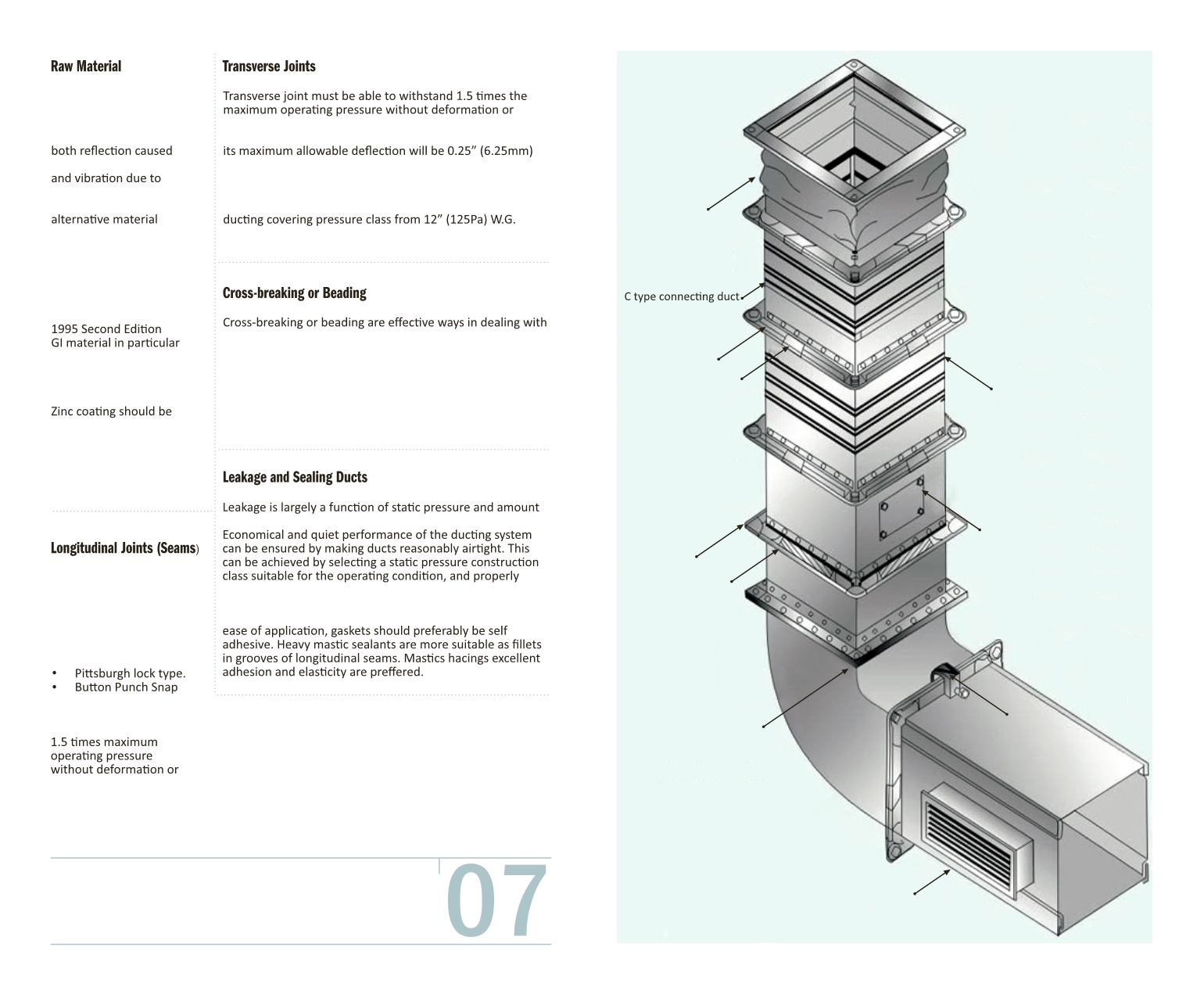

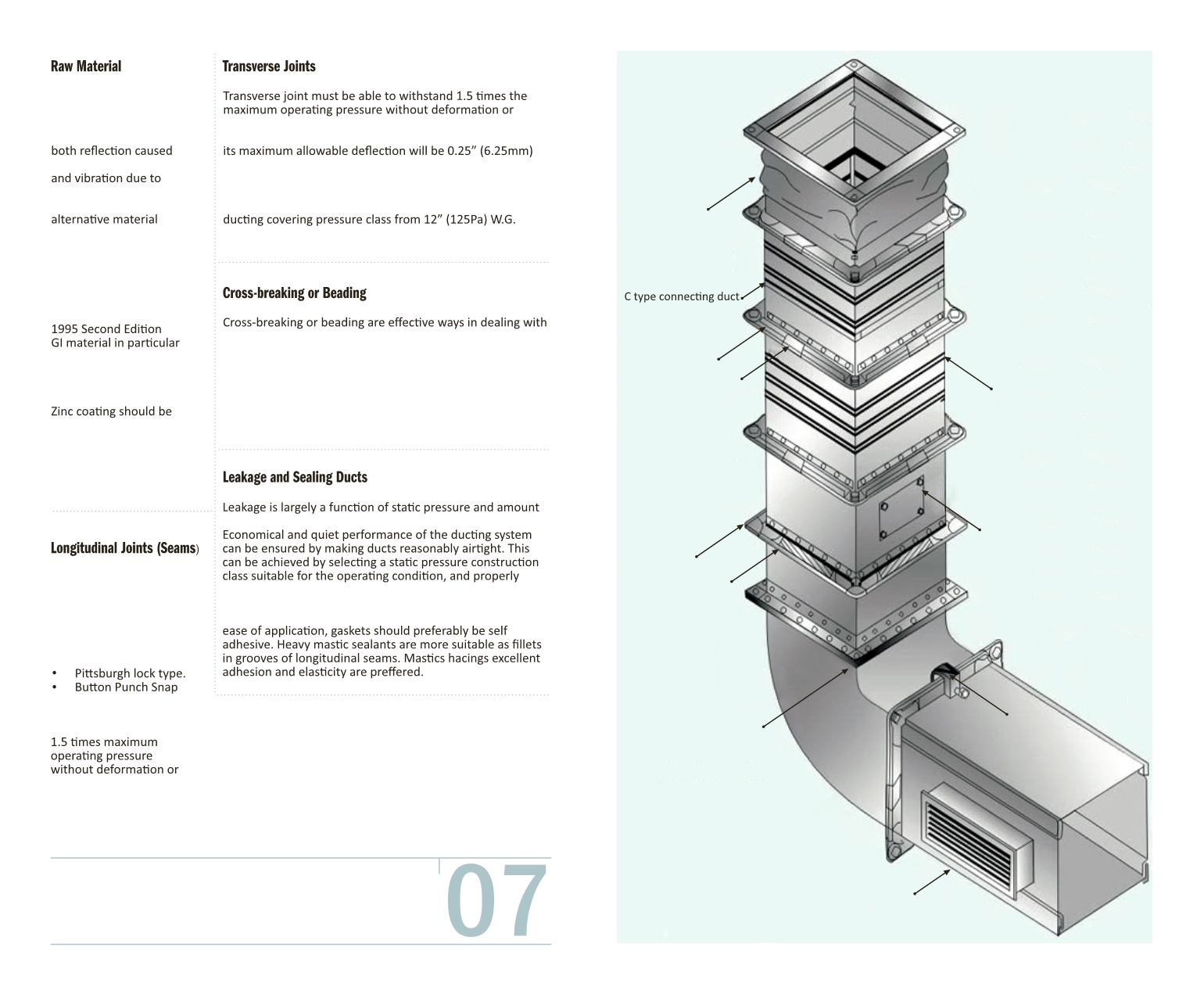

Air Grille

TDC Duct

TDC Corner

TDC Clamp

Beading

Duct Access Door

Duct Flange Clamp

Duct Flange

Corner Flange Duct

Duct Flexible Connector