With more than 260 skilled operators and fabricators,

CMI is able to execute work in excess of 50 million SAR

annually. Quality Control (QC) system has the top priority in

all CMI products. To ensure it, Quantity Assurance (QA) plan

is implemented where the QA officer checks every element

during the production and again before it is delivered. QA

checklist is followed during all stages of operation.

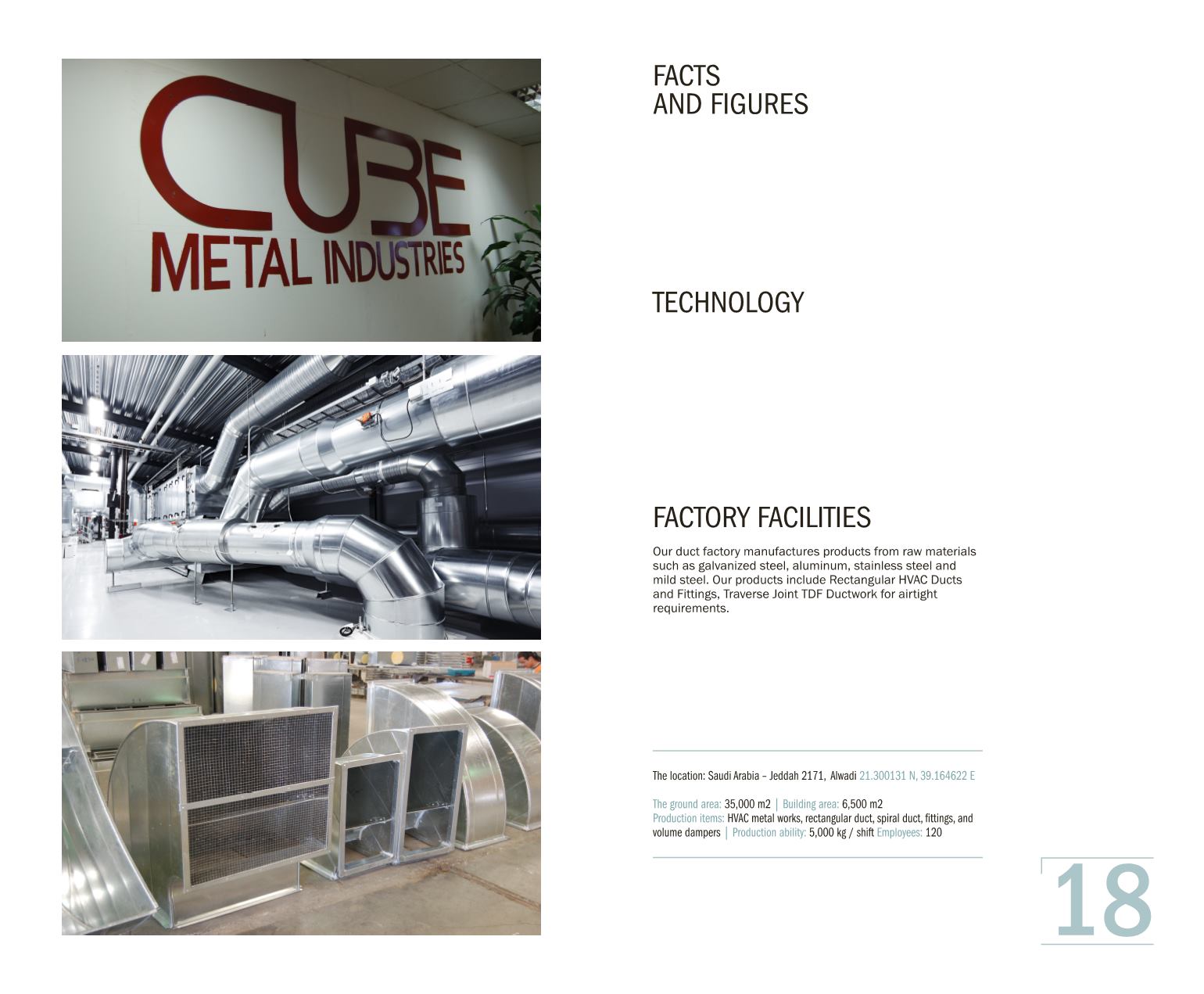

Using the aid of the latest fabrication software, the shop

drawings are located to the central PC where the various

nesting reports of the duct parts are sorted out and the

instruction from the PC is transmitted to the CNC Plasma

cutting machine. After the cutting, a bar coded label will

be automatically installed on duct parts where it will proceed

to the assembly. The usage of the highly sophisticaded CNC

machines give CMI a quality edge over its competitor.